-

-

-

Tổng tiền thanh toán:

-

TẦM QUAN TRỌNG CỦA VIỆC KIỂM SOÁT ĐỘ ẨM TRONG SẢN XUẤT

Độ ẩm trong sản xuất có tầm quan trọng như thế nào? Trong nhiều lĩnh vực sản xuất và quá trình sản xuất, kiểm soát độ ẩm là yếu tố...

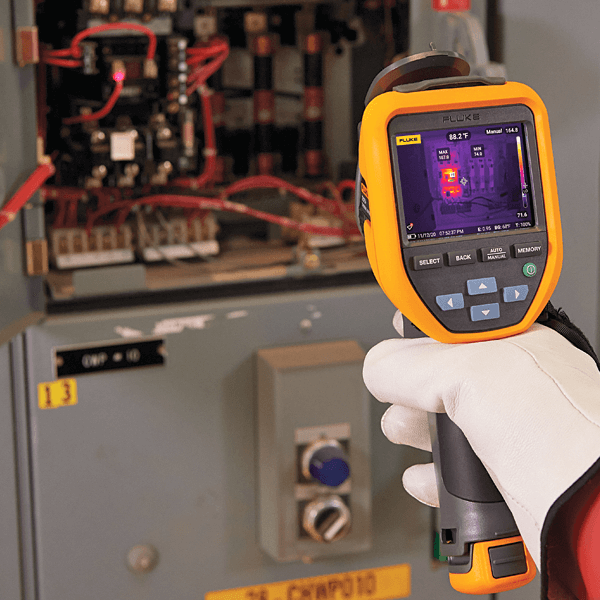

Kiểm tra nhiệt độ HT Điện

Kiểm tra nhiệt độ HT Điện

Kiểm tra phóng điện

Kiểm tra phóng điện

Kiểm tra chất lượng nguồn điện

Kiểm tra chất lượng nguồn điện